Don’t wait till summer to fix an underperforming system!

As the high production season approaches, smart solar maintenance strategies ensure your solar system operates at peak efficiency. Taking a proactive approach secures your investment and can catch critical system issues before they become serious problems.

-

Maximize energy output for the high production summer season

-

Prevent unexpected and costly repairs

-

Extend the lifespan of your equipment

Our comprehensive solar maintenance strategies prepare your system for optimal performance during the sunniest months.

1. Schedule an Onsite Inspection

We begin with a thorough assessment of your solar installation with a deep dive into system equipment, capabilities and output. The goal is to optimize your system’s performance before summer hits.

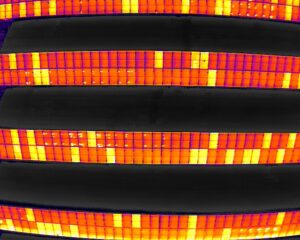

- Infrared Thermography: Equipped with the latest thermal drone capabilities, our technicians can survey your site and pinpoint malfunctions.

- Electrical Connections: Check wiring and connections for signs of wear or corrosion. Faulty wiring can lead to power losses or safety hazards.

- Manufacturer Recommendations: Identify and complete maintenance to ensure your system works just as it should.

2. Plan Ahead for Changing Site Conditions

Environmental factors can have a big impact on your systems efficiency. CES O+M can help you craft a plan that addresses issues before they become problematic and affect your bottom line.

- Regular Panel Cleaning: Establish a routine to remove dust, dirt, and bird droppings. Accumulated debris can reduce efficiency by up to 25%.

- Vegetation Management: Prevent safety issues, electrical damage, and production loss caused by overgrown vegetation. It is important to keep cable trays, inverters, and all equipment free from obstructions.

3. Take Advantage of Remote Monitoring

Remote monitoring software allows our analysts to identify and resolve system issues.

- Performance Tracking: Tracking daily energy production can reveal sudden drops in output can indicate underlying issues needing attention.

- Benchmarking: Compare current performance data with historical records to identify trends and address inefficiencies promptly.

4. Implement Proactive Maintenance Strategies

Our team uses measures that anticipate and prevent potential issues:

- Predictive Analytics: Utilize data analytics to forecast equipment performance and identify potential failures before they occur. This approach allows for timely interventions, reducing unplanned downtime.

- Scheduled Component Checks: Regularly inspect and replace aging components such as inverters and batteries to maintain system reliability.

5. Develop a Comprehensive O&M Strategy

Beyond the standard annual inspection, we have the tools and knowledge to build a broader strategy to not only keep your system running but to completely optimize its performance.

Why Chose CES O&M?

A proactive maintenance program is key for efficient site management. We employ highly trained technicians and engineers who provide in-depth assessments using advanced diagnostic technology. Nationwide, our customers trust us as a true partner with the expertise to guide them towards maximum solar productivity.

Contact us today for expert advice on the best service plans for your solar assets. From annual inspections to active monitoring, visit our Operations & Maintenance page for a comprehensive list of services.

service@cesnrg.com

(630) 637-2150