Our newest series “Solar Sightings” gives a behind the scenes look by highlighting case studies from the field.

Technician’s Log 2022-02 – CES Solar Monitoring Detects Tricky Tracker

SITE DESCRIPTION: 2.851 DC, Single Axis Tracker (SAT) Ground Mount, Community Solar

REGION: Midwest

REMOTE MONITORING FINDING: Onsite equipment failed to detect tracker failure that was picked up through remote solar monitoring

SOLUTION: Advance knowledge of the problem equipped techs with the location, tools and parts needed for a fast response.

![]()

Remote solar monitoring is arguably the most important tool in the O&M tool belt (sorry field techs!). Metrics, equipment and system health information, security, and reduced service calls translate to higher rates of production with an eye on the bottom line.

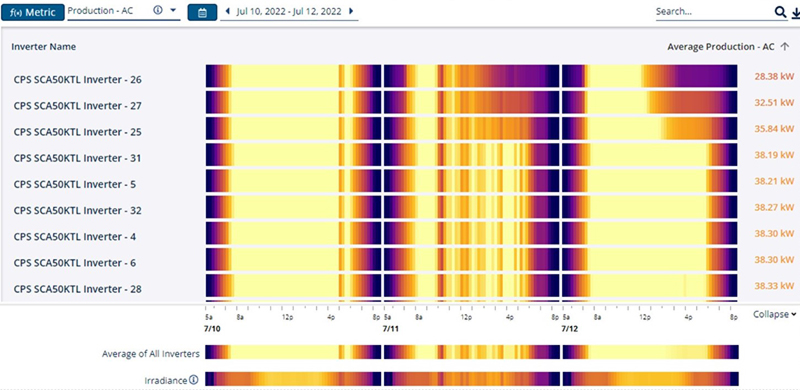

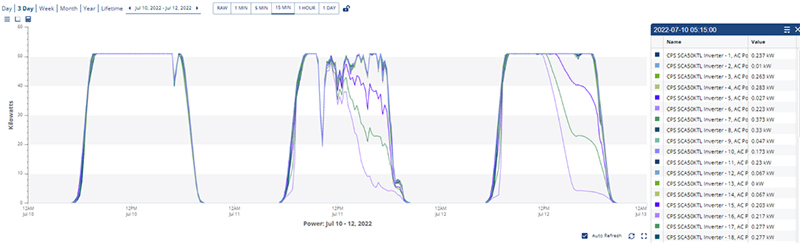

The equipment on site could not detect this active failure, but our custom designed solar monitoring filters generated a valuable alert for unexpected production changes. The metrics collected allowed us to perform inverter comparisons through heat maps and data curves. We determined that the trackers were the culprit. The inverters were only producing on one half of the day, which suggested that they were not moving with the sun.

![]()

Knowledge is power. Dispatched with the tools and material commonly needed to service this manufacturer’s parts, our techs were prepared. The CES Monitoring group were able to provide a map to pinpoint the problem area, eliminating the need for a site inspection. Once on site, it was determined that the drive shafts were not changing the angle of the inverters because they fell out of their connectors and were continuing to rotate free on the ground. All of the prep work done in advance of the visit ensured the issue was resolved quickly.

Takeaways:

CES Solar Monitoring Group works for your assets. With our expertise, all of your solar remote monitoring design, installation and configurations are handled. This translates to:

Powerful Data: The base metric of metering site production provides the data for revenue from SRECs, Net Metering, and Leasing charges, and PPAs. Dollars for kilowatt hours is the name of the game. CES can generate automated, custom reports for your data needs.

Equipment Health: Inverters are getting smarter with every generation. For example, some SMA inverters can generate an MPPT level IV Curve Traces, and many can tell exactly what ails them. CES Monitoring has experience with every major equipment manufacturer to understand and respond when needed.

System Health: Before a site is constructed, modeling is used to determine how much electricity it will generate. The models include predictions of the most impactful variables: temperature, precipitation, and irradiance. Monitoring with POA / GHI, temp sensors are used to see if the site is performing as predicted in real time, revealing systemic issues like soiling, shading, incorrect inverter programming, CT ratios, and more. CES uses this data in predictive failure and catches issues proactively.

Monitoring Security: As our world becomes more interconnected, the security of our grid tied equipment is critical to the safety of our infrastructure. Cyber security threats can lead to damage to equipment, system, servicing tech and utility. CES O&M works with IT groups to ensure cyber security threats are prevented from the start.

Reduce Costs: CES prioritizes productivity for our clients. Our remote monitoring group can eliminate the need for truck rolls through remote diagnostics and configuration changes, or by reducing field time through diagnostic localization.

Contact us today for expert advice on the best service plans for your solar assets. From annual inspections to active monitoring. Learn how our services can boost production and prevent downtime.

service@cesnrg.com

(630) 637-2150