Our newest series “Solar Sightings” gives a behind the scenes look by highlighting case studies from the field.

Technician’s Log 2022-01 – Routine Solar Inspection Leads to Emergency Shutdown

SITE DESCRIPTION: 1.165 MWDC, Fixed Ground Mount, Utility Solar

REGION: Midwest

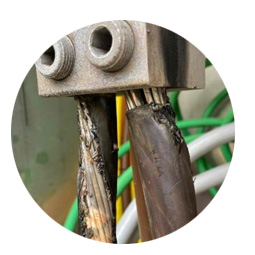

FIELD FINDING: Melting feeder insulation, severe overheating, fire hazzard caused by improper termination lugs for wire type at installation

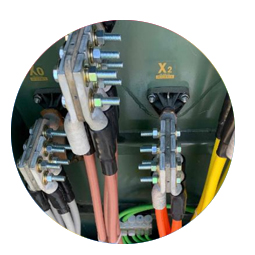

SOLUTION: Removal/installation of all new feeders, terminations, and testing.

The O+M department at CES gained a new asset for solar maintenance. Little did we know how important that acquisition to our Midwest Portfolio would prove to be for our client. Our first visit was to perform a standard Preventative Maintenance Inspection. No special testing or thermal drone scans, just a normal inspection to ensure everything was tight, operational, and producing to its potential.

Upon opening a system transformer, we immediately noted charring, melted insulation and the distinctive smell of active burning. The client was immediately notified that we had to perform an emergency shutdown for safety reasons and the PMI came to a screeching halt.

To minimize downtime, we quickly sent a proposal to replace the feeders, terminations, and fully test out the corrective work. The client approved the scope, which allowed CES to dispatch within days. Our vendor network rallied to expedite material and, our field labor coordinator organized the crews to get system back in operation as quickly as possible. CES went from discovery to full operation within the week during the peak season.

To minimize downtime, we quickly sent a proposal to replace the feeders, terminations, and fully test out the corrective work. The client approved the scope, which allowed CES to dispatch within days. Our vendor network rallied to expedite material and, our field labor coordinator organized the crews to get system back in operation as quickly as possible. CES went from discovery to full operation within the week during the peak season.

Takeaways:

- Solar Maintenance Matters! A preventative maintenance program caught this problem before it became more serious. Expert technicians make the difference and protect your solar investment.

- Even if we did not build it, we can still help secure your investment. Our field knowledge can ensure your solar construction is installed correctly. From making sure everything is up-to-code and plans are followed, to ensuring the implementation of best practices, the right solar maintenance team translates to saving substantial amounts of O&M costs down the line on future repairs.

- Our technicians are the best in the business. We put a badge of service quality on every site due to their expertise and diligence. Highly trained, NABCEP certified technicians, engineers, and our vendors know that quality O&M work is our model. We carry out ANY scope of ANY size quickly, professionally, and affordably to make sure your uptime is maximized during the most critical production days.